Honda CivicX Turbo Inlet Pipe Prototype Images – Design Pt. 2

A few weeks ago we decided to investigate the little discussed plastic intake pipe that connects the intake system to the turbocharger; we named this component the Turbo Inlet Pipe (TIP). You can check out part 1 here. We asked the question: Is the stock TIP compromising performance?

Flow bench testing told us there most likely are potential gains from a performance Turbo Inlet Pipe. What we didn’t expect was the overwhelming response from all of you regarding just how ugly the stock TIP is.

Because of the potential for performance improvements AND the strong response about aesthetics we decided to explore this project further. Check it out below…we promise you won’t be disappointed.

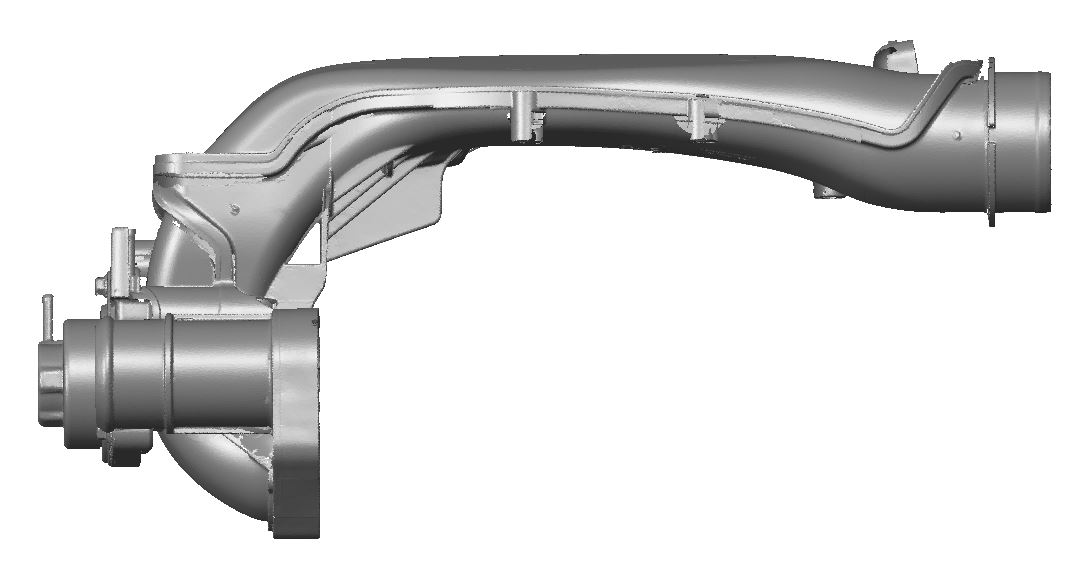

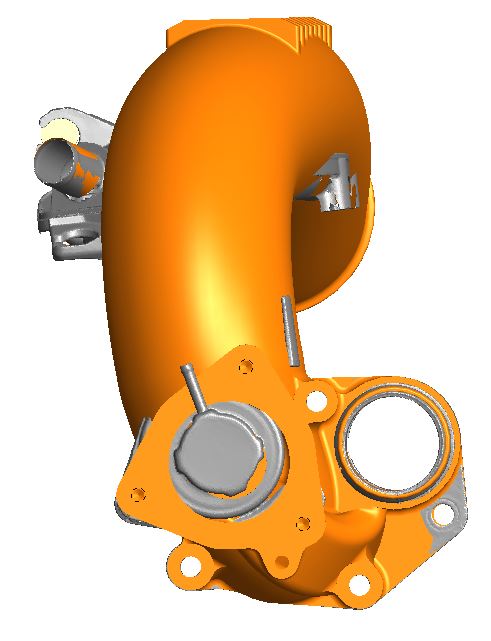

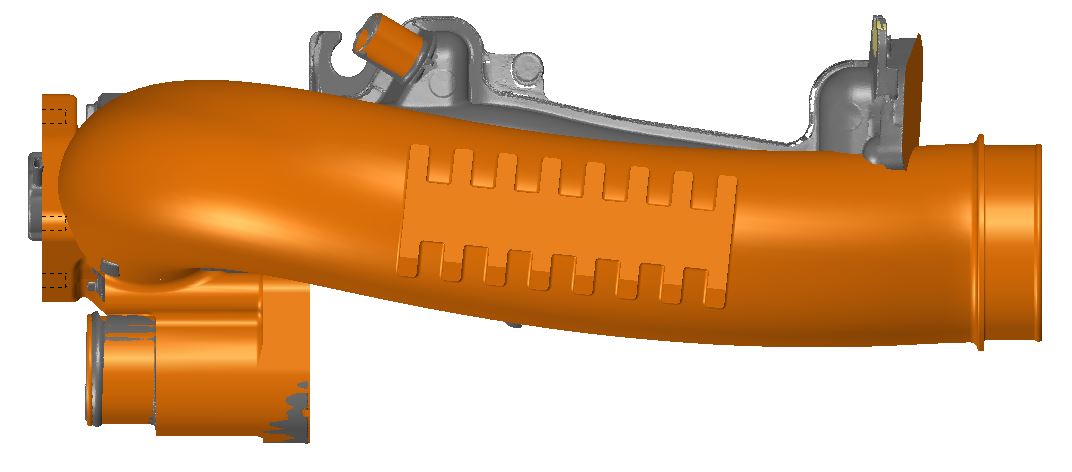

Our next step was locating all critical surfaces and features of the pipe. We captured this information with our 3D scanner that creates a virtual 3D image of the part. With this information transferred directly in CAD software, we can now quickly and accurately create and iterate prototype designs.

While the L15 variants utilizes a plastic TIP the K20C1 as found in the FK8 is made of cast aluminium

When we explored prototype designs for our 27WON Turbo Inlet Pipe we had to consider how we will manufacturer it because the type of manufacturing will greatly affect the overall cost, fitment, ease of use, and the visual appeal.

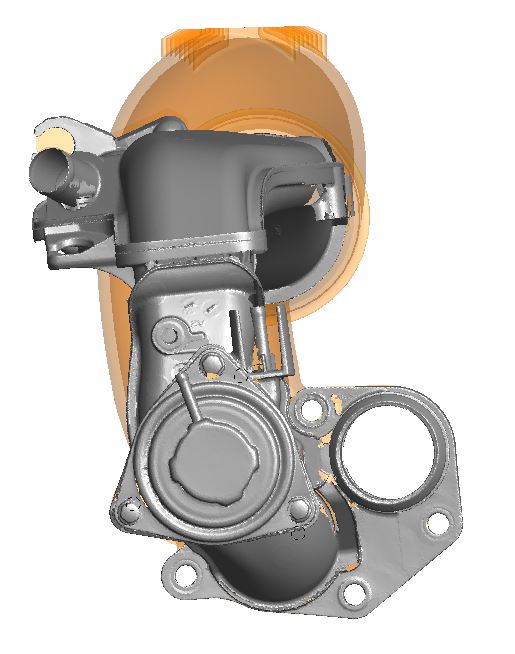

We considered a plastic rotomolded part similar to the cold air box in our CAI System for the SI and Non-SI Models, but it has some design constraints. We considered a more conventional path with aluminum piping, a large silicone coupler, and a billet adapter plate to the turbo compressor inlet, but this left a major issue… what would we do with the Bypass Valve (BPV)?

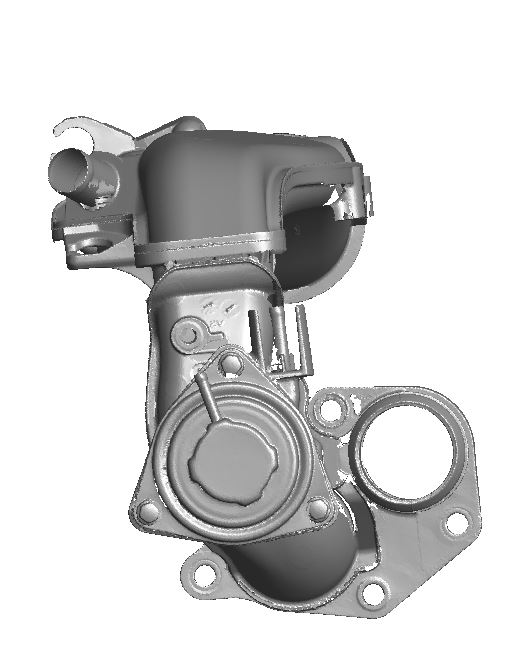

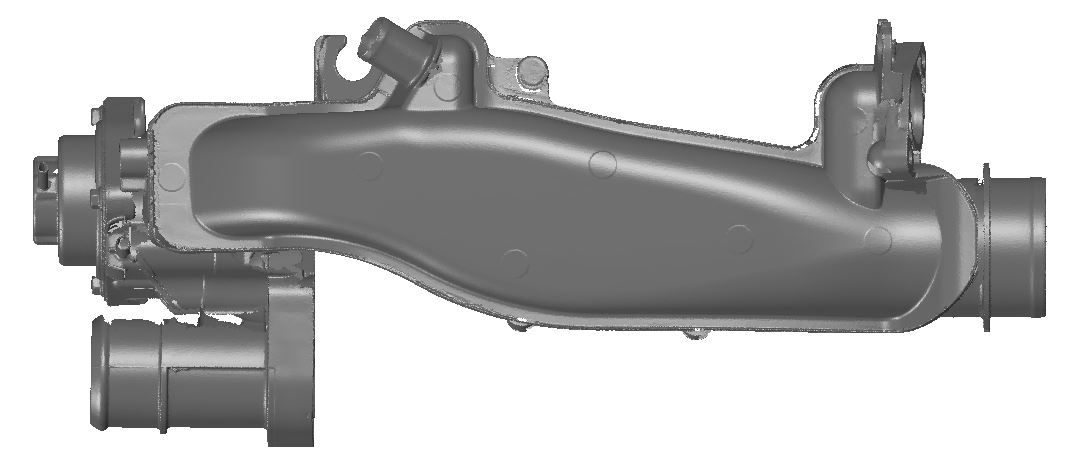

Instead, we turned to Honda for inspiration…the FK8 Civic Type R. Here we found a path that could provide us with the design flexibility we need to increase the overall size and thus performance, allow us to integrate the OE style BPV, and create a performance part that would look as great as it performed. This type of manufacturing is aluminum casting.

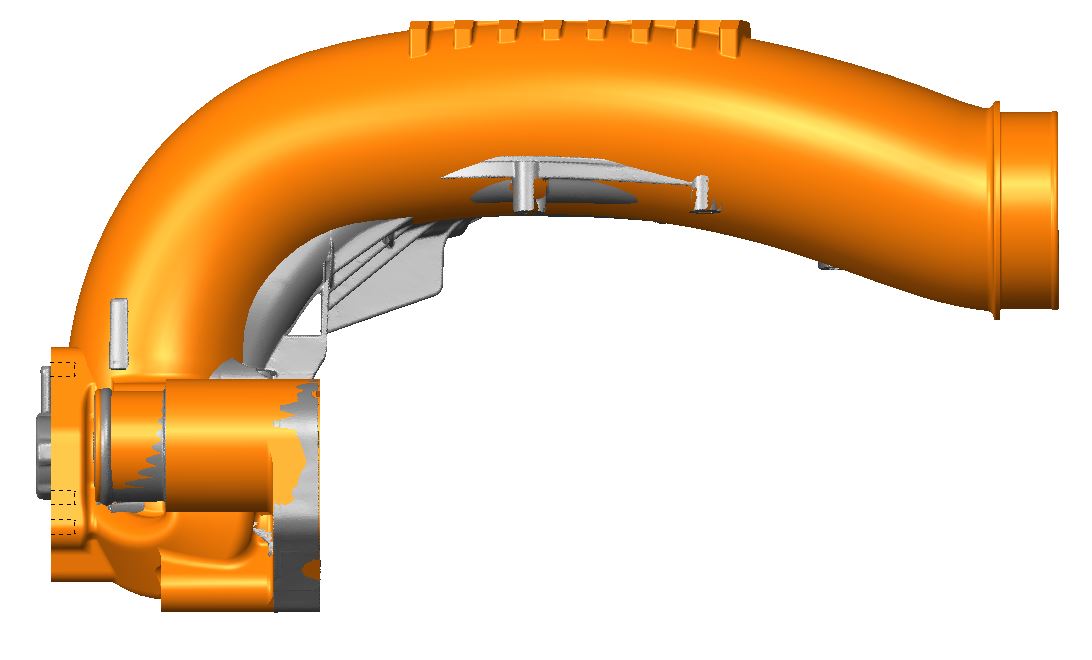

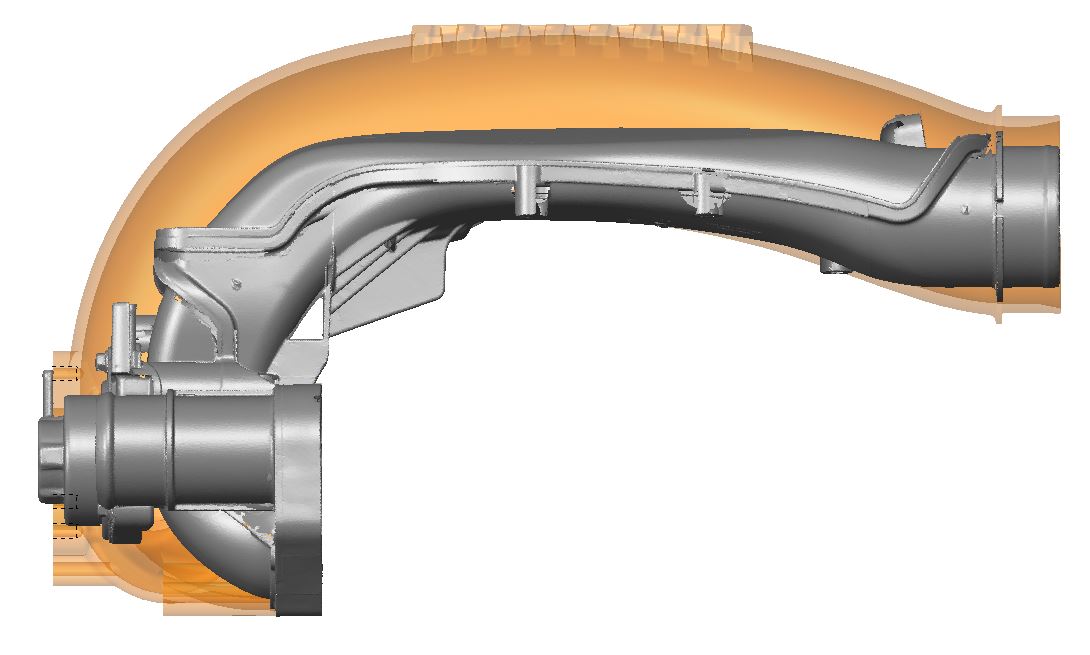

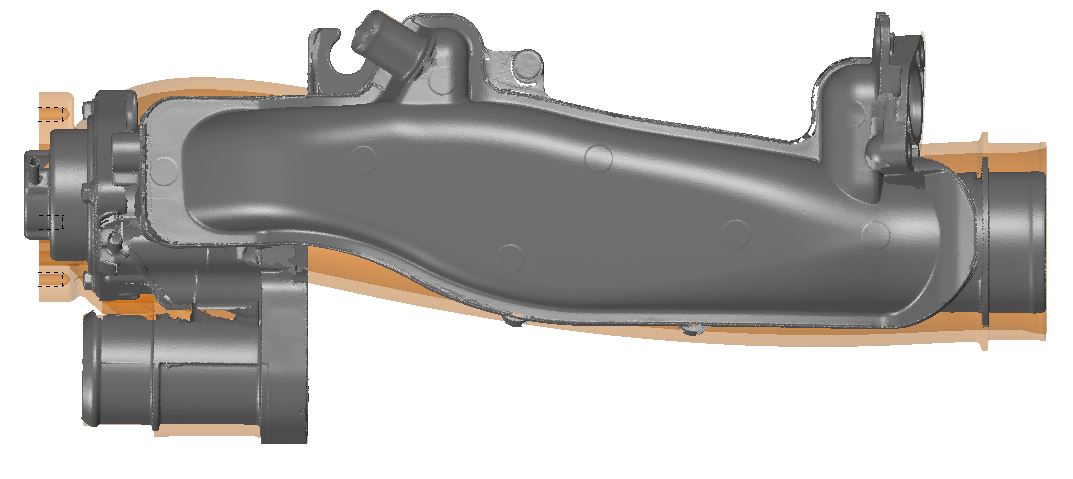

In the images above you can see the orange prototype design of the 27WON Turbo Inlet Pipe and you can also see the power of the CAD software. With the scanned copy of the OE turbo inlet pipe, we can precisely compare the OE and 27WON designs. What you can’t see yet, is just how much larger the 27WON design is compared to the OE turbo inlet pipe.

If bigger is better than we present to you the best

This translucent version of 27WON TIP gives you a better understanding of the size difference. Our TIP is SUBSTANTIAL!

The “pancake” is long gone and in its place is a more conventional round profile. This concept is subject to change as we continue refining it but it tells us that a high performance turbo inlet pipe is a feasible project.

We’ve really enjoyed this project so far, but we need to know what you think! Do we keep pushing forward with the 27WON Turbo Inlet Pipe? Let us know by dropping a comment below.

Thanks for tuning in with 27WON Performance. WE DARE You to REDEFINE the Aftermarket

-Barett