2022+ Civic OE Intercooler System Breakdown, Design Blog Pt. 1

Today, we are going to take an in-depth look at the OEM Front Mount Intercooler on the 2022+ Honda Civic EX, Touring, and Si. I am really excited to explain this system to you in detail because it has some really trick and interesting features that you may not know about. We have spent a lot of time over the past few weeks going through and dissecting the system inch by inch and below is a summary of what we’ve uncovered.

Now, before we dive too deep into this, if you’re a new 11th gen owner and just came across this blog then I want to welcome you. One thing we emphasize here at 27WON is educating people about the OEM systems found on their car. We dive into aspects of a component in detail and explain to you how it works so that when you are shopping for an aftermarket upgrade in the future you know exactly what to look for.

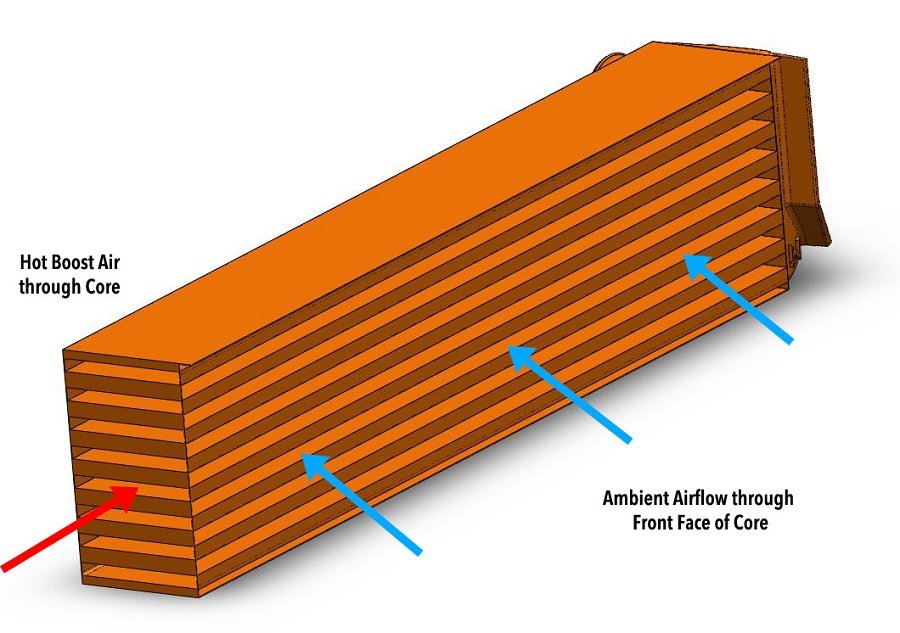

On to the good stuff! The Front Mount Intercooler or FMIC as you will see it referred to is a heat exchanger that is fitted to your L15 turbo engine and is designed to take the hot compressed air exiting your turbocharger and cool it down to more dense air before entering the engine. This heat removal is completed via the use of an air to air cooler. It uses cooler air from the atmosphere (i.e. outside air) to pass over the hot air coming out of the turbocharger. It does this with a “core” made up of a bunch of fins and passages via convection. It looks like the example below.

Simulated air flow through an 27WON intercooler

This heat exchanger, aka the “core”, portion of the FMIC kit sits right behind the lower part of the front bumper. It uses a series of hard plastic and rubber pipes to route the air from turbo all the way back to the throttle body. The rubber pieces allow for some engine movement and ease of installation. These parts are very small in diameter which leaves plenty of opportunity for an aftermarket upgrade kit.

Honda Civic front end and oem intercooler core location

Here is a view of the entire intercooler system removed from the car. You can clearly see the “cold” side pipes (right side) and the “hot” side pipes (left side) and the core itself. This piping is composed mostly of rubber and plastic. Affordable to make but not ideal for power or performance as they are not as strong as aftermarket materials and are small in size.

A complete view of the front mount intercooler system on the 2022 Honda Civic

Starting from the compressor outlet, you have a simple rubber tube secured with a pair of worm gear clamps going to a hard plastic pipe. Rubber has a tendency to wear out and get brittle from heat over time so a material change here is a nice upgrade.

Past this rubber hose section, we see a plastic hard pipe and end tank with two back-to-back 90 degree turns as air enters the intercooler core. This OEM design works within all the tight spaces behind the front bumper. A closer look tells us we could make these larger and smoother to allow the air to move into the core more freely. Air is fluid and fluids are lazy. They will always take the path of least resistance when given the option so helping put the air where we want it to go is key for performance.

A view of the front mount intercooler side tank

One thing I want to draw your attention to is the OEM plastic end tanks. See how it looks like there are a bunch of cubes cut into it? Those are actually there intentionally and serve a very important but often misunderstood purpose! Each of those little squares acts like a mini heat sink to help remove heat from the hot charge air inside the intercooler. Remember, the number one purpose of the intercooler is to draw hot air out as efficiently as possible. Anything that can be done to promote this is the desired effect.

Plastic used for the end tanks on the front mount intercooler

The intercooler core itself is nothing to brag home about. At 24” wide and 4.5” tall, it’s rather dinky in size and has the ability to heat soak rather quickly. Heat soak is just what it sounds like. The intercooler itself heats up which makes it less effective. Upping the size of the core in both length and width will allow for more surface area to reject heat.

Moving to the outlet side of the FMIC, you see the same cube-like pattern on the end tank to reject heat. Past the end tank, we see a plastic pipe connected to a rubber hose that leads to, of all things, a resonator! This interesting component is a carry-over from the 10th generation Honda Accord. This resonator is found right behind the driver-side fender well area. This bulky piece of plastic is here for no other reason than to take cool sounds away from you! It takes fun induction noises from us, so needless to say it has to go.

Honda plastic end tank on the cold side of the system

An OEM resonator design from Honda

Finishing out the air path, the now cooled air coming out of the FMIC goes through another rubber hose into a plastic hard pipe that has a bunch of important sensors fitted to it. Air then takes one final left turn as it goes into your throttle body. The sensors measure Manifold Absolute Pressure and intake air temperature. Both give key data to the PCM (engine computer) to make sure the car is running right. Keeping these is a must.

The path of intercooler piping leading to the throttle body

As you can see, there are a lot of components that go into the intercooler system on your 11th gen Civic. The core, end tanks, hard pipes, rubber hoses, clamps, and sensors all play a role the system and it's only right that when the time comes, you look to upgrade to a system that takes all of these factors into consideration. Leave no power on the table and don’t settle for less.

We hope you found this blog informative and if you have any other questions about the FMIC, drop us a message below.

REDEFINE the Aftermarket

-Vincent