CivicX Front Strut Tower Brace – Rigid Strength Design Pt. 2

The 27WON Performance Front Strut Tower Brace (FSTB) is a design that is unlike anything else on the market today. Let’s talk about why this is so.

When we approached this project we wanted to develop a FSTB that both looked great (complimenting the body lines of the 10th Gen Civic) and performed well (it needed to be rigid). Featuring mild steel construction with fixed endplates and a twin-tube design; the 27WON Strut Tower Bar combines form and function.

This slim design pushed us to use smaller diameter tubing for the crossbars. This could reduce rigidity. To maintain strength and function we employed a second thick-walled tube to increase the rigidity and buckling strength.

The second crossbar allowed us to add unique style as the bars diverge from each other and connect to the endplates. This brings the converging & diverging body lines of the Civic into the engine bay.

Now let’s talk about strength and rigidity a bit more. There are two common designs for Strut Tower Braces in the market today. Bolted Endplates and Fixed Endplates. The endplates are how the bar mounts to your strut towers.

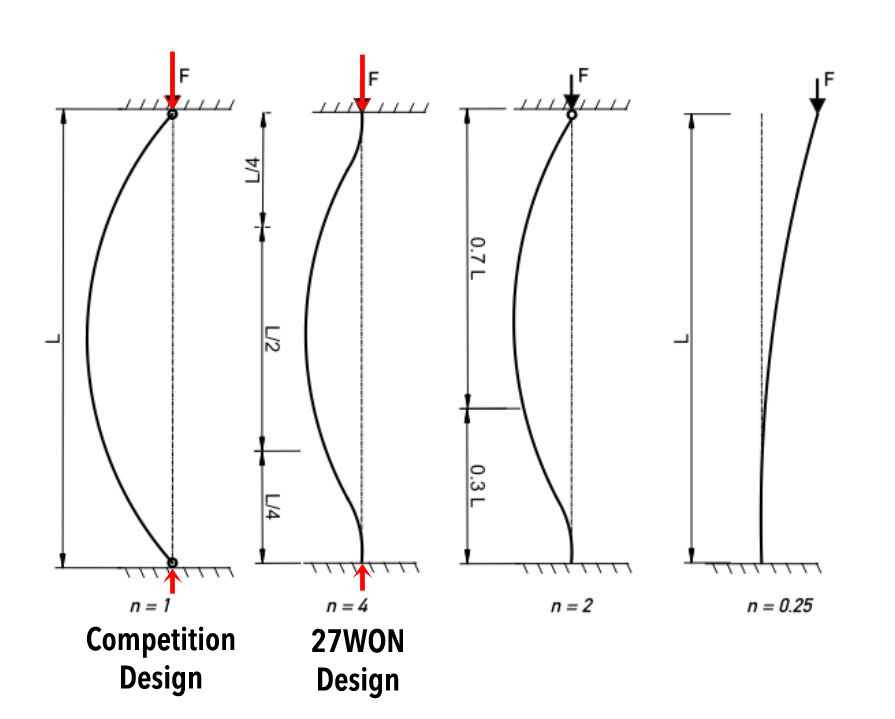

Check the equation at the end of the blog to see how the math works out

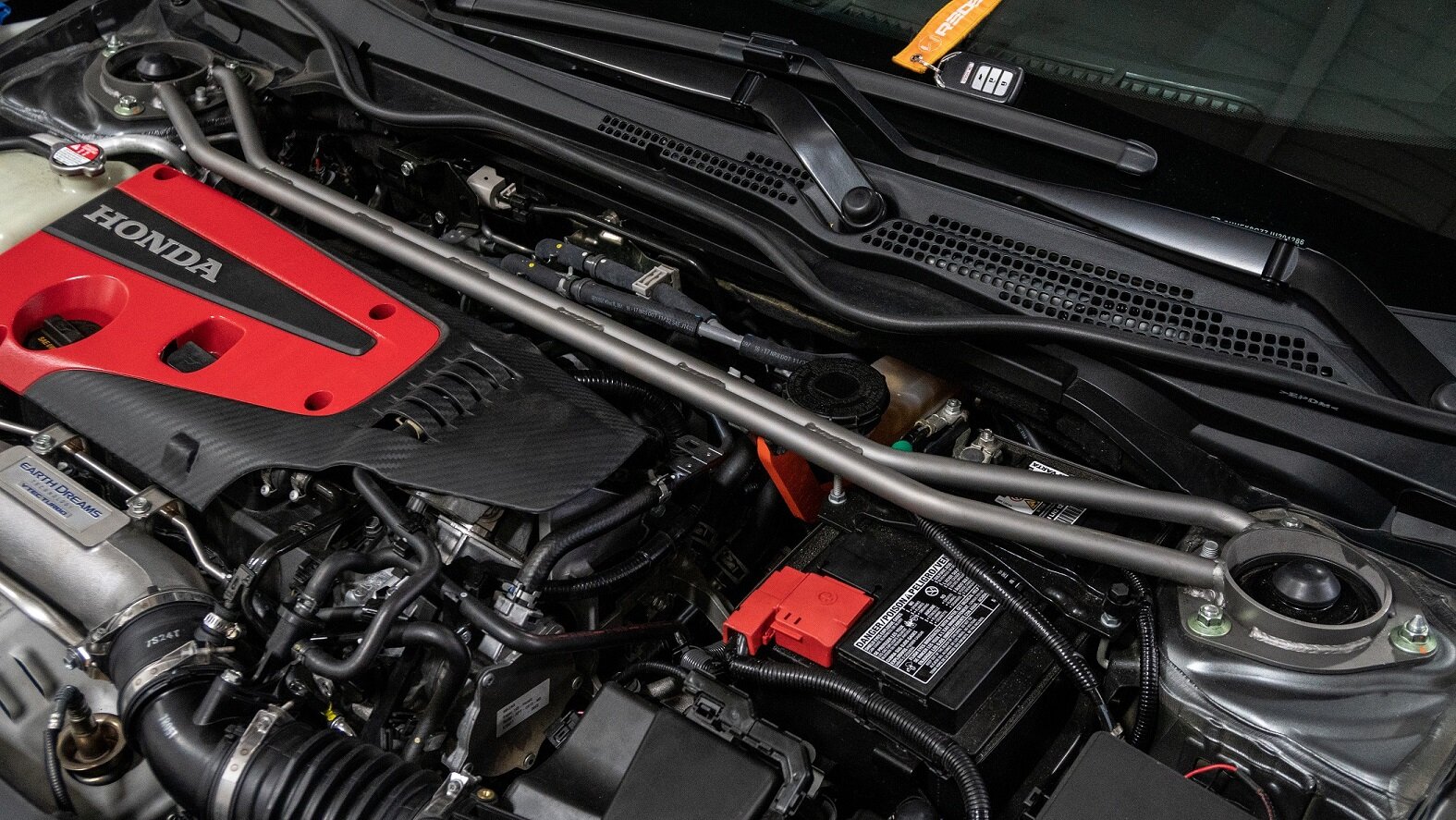

Take note of the red arrows…this represents force from the suspension transferring from the strut tower into the brace endplates.

Bolted endplate designs allow for the use of different materials for the crossbar and the endplates and thus are much easier to design and manufacture. However, the design has an inherent weak point; the bolted connection between the crossbar and endplates. In single bolt connections the rigidity (buckling strength) of the brace is compromised by a factor of 4!

Fixed endplate designs typically utilize a single material for the crossbar and endplates welded construction. This results in a more complex manufacturing method but the result is a design that is 4 times stronger than the alternative. Check the quote at the end of this article for more on Euler’s equation if your into that sort of thing.

Here are the same red arrows overlaid on the engine bay. As the forces are pushed into the brace the brace begins to resist the load. This is how a strut tower brace increases the chassis strength. If the brace is not strong enough it will buckle like the diagram above and thus not function optimally.

So now you know why a fixed endplate design is superior. Not only is it using the material strength but it is also benefiting from the fixed connection between the crossbar and endplate.

Stayed tuned as we continue the development of our 27WON Front Strut Tower Bar. Soon we will be sharing a special color option and announcing a release date. Until then…I DARE You to REDEFINE the Aftermarket

-Barett

Reviewing Euler’s Equation for Buckling: F = n π^2 E I / L^2

F = Allowable Load

n = factor account for end conditions (this is the main design criteria we are discussing)

E = modulus of elasticity (this is the material strength)

L = length of column (this is the distance between the strut towers)

I = Moment of Inertia (this is the diameter of the tubes in the FSTB)